Table of Content

The global supply chain landscape is undergoing a remarkable transformation. And this is seriously driven by the integration of AI in supply chain.

AI has emerged as a game-changer in this evolution, offering capabilities that extend far beyond traditional supply chain management tools. Whether it is about predictive analytics or autonomous decision-making- AI is transforming how businesses forecast demand, optimize inventory, streamline logistics, and enhance customer satisfaction. The numbers speak for themselves.

According to McKinsey, companies implementing AI in their supply chains have reduced forecasting errors by 20-50%. Plus, these have reduced the logistics costs by up to 15% (McKinsey & Company, 2021).

In this comprehensive guide, we’ll explore how AI is reshaping supply chain management, examine its key applications across different functions, and look ahead to emerging trends that will define the future of intelligent supply chains.

AI in supply chain management refers to the application of advanced algorithms, machine learning models, and data analytics techniques to optimize and automate supply chain operations. These are different from the traditional rule-based systems

AI is capable of analyzing enormous volumes of both organized and unstructured data, identifying patterns, adjusting to shifting circumstances, and coming to wise conclusions.

Fundamentally, supply chain management with AI includes:

Over the past ten years, supply chain management’s use of AI has changed dramatically. Modern AI systems now include cognitive capabilities that can comprehend context, learn from experience, and make increasingly independent judgments. Originally, these systems were centered on basic automation and rule-based decision support.

According to IBM, businesses that use AI-powered supply chain management can reduce forecasting errors by 40% and lost sales from inventory out-of-stock scenarios by up to 65% (IBM Supply Chain Intelligence Suite, 2022).

A number of reasons have contributed to this evolution:

As these technologies develop further, supply chain management is moving from reactive to proactive—that is, from fixing issues after they arise to foreseeing and averting problems before they affect operations.

Since it influences decisions about inventory, manufacturing, staffing, and procurement, accurate demand forecasting is arguably the most important function in supply chain management.

AI has revolutionized this area by:

An MIT study claims that when compared to conventional statistical methods, AI-driven forecasting systems can cut mistakes by as much as 50% (MIT Sloan Management Review, 2022).

Prominent retailers such as Walmart are using artificial intelligence (AI) to estimate demand. Their system processes 1.5 petabytes of data each hour to optimize inventory levels across more than 11,000 stores. Customer satisfaction has increased dramatically and out-of-stocks have decreased by 16% as a result of this adoption (Harvard Business Review, 2022).

For supply chain managers, striking a balance between preventing stockouts and reducing excess inventory is a constant struggle. AI addresses this challenge by:

Target significantly outperformed industry averages by implementing an AI-driven inventory management system that maintained a 98% in-stock rate while reducing carrying costs by 15% (Supply Chain Dive, 2023).

To maximize inventory optimization, AI systems typically integrate with:

This holistic approach ensures that inventory decisions are aligned with actual market conditions and operational constraints.

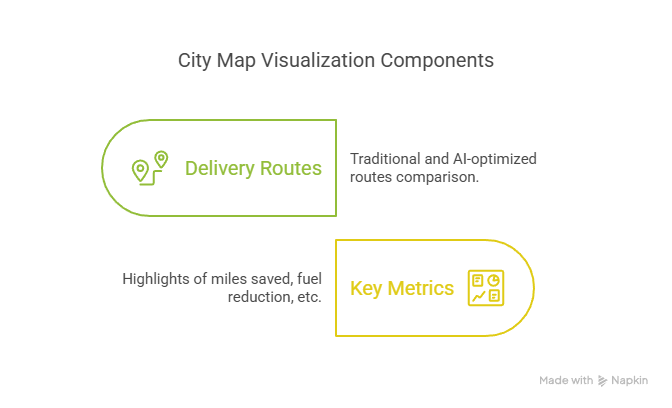

AI is transforming logistics execution through intelligent route optimization that considers multiple variables simultaneously:

DHL’s AI-powered optimization engine analyzes 58 different parameters to determine optimal delivery routes, resulting in a 15% reduction in vehicle miles and a 10% decrease in carbon emissions (DHL Supply Chain, 2023).

Beyond route planning, AI enables dynamic rerouting based on real-time conditions. If a traffic jam suddenly develops or a high-priority order comes in, the system can automatically recalculate routes for the entire fleet within seconds—something that would be impossible with manual planning.

The economic impact is substantial: UPS estimates that reducing just one mile per driver per day saves the company $50 million annually, highlighting the significant ROI potential of AI route optimization (UPS Pressroom, 2022).

AI is coordinating the flow of humans, commodities, and robots in modern warehouses, which are becoming more and more automated spaces. Important uses consist of:

Intelligent slotting reduces picker trip time by up to 30% by using AI to assess order patterns and place fast-moving items in the best possible spots.

• Autonomous Mobile Robots (AMRs): AI-driven robots that move objects between sites or deliver products to pickers while navigating dynamically around warehouses.

• Computer Vision for Inventory: By removing the need for human cycle counts and minimizing inventory inconsistencies, these systems are able to visually detect and count things.

• Predictive labor planning: AI predicts patterns in warehouse workload and suggests the ideal number of employees for each zone and shift.

With humans and machines collaborating in perfect harmony, Amazon’s AI-driven fulfillment centers handle millions of orders every day, allowing same-day delivery possibilities that were unthinkable just ten years ago. (Amazon Operations, 2023).

The outcomes are striking: when compared to traditional operations, warehouses using AI-driven management systems show 25–40% increases in productivity and up to 90% decreases in errors (Deloitte Supply Chain Digital Transformation Survey, 2023).

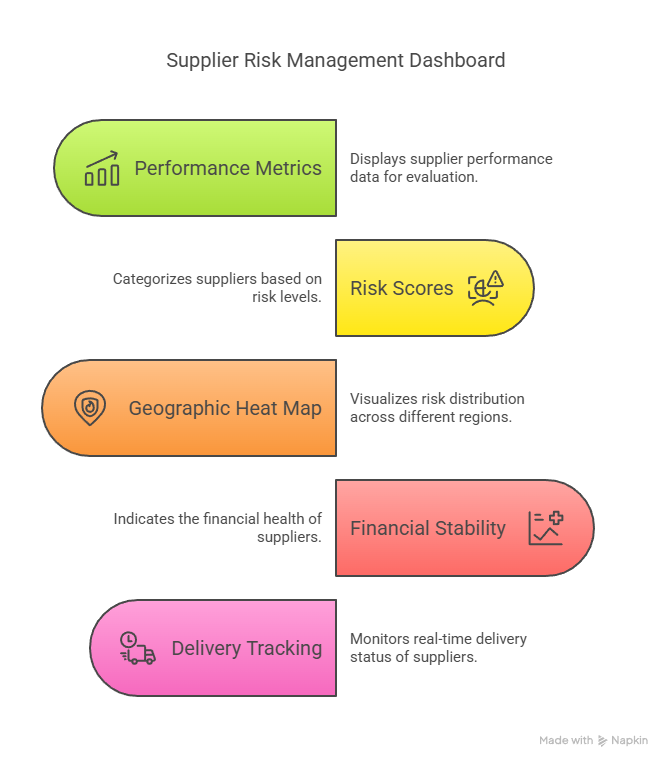

AI transforms supplier management from a reactive, transaction-based function to a strategic, proactive partnership by:

Unilever reduced supply disruptions by 17% and procurement expenses by 4% by implementing an AI-powered supplier management platform that examines more than 100,000 suppliers in 190 countries (Supply Chain Management Review, 2023).

These solutions give procurement experts previously unheard-of insight into supplier networks, including nth-tier suppliers that could normally go unnoticed. When main supply chains were damaged during recent global upheavals, businesses with sophisticated AI capabilities were able to immediately shift thanks to this visibility.

Costly supply chain interruptions can result from equipment breakdowns in manufacturing plants, distribution hubs, or fleets of vehicles. AI addresses this challenge through:

Manufacturers implementing AI-powered predictive maintenance report up to 40% reduction in downtime and 25% decrease in maintenance costs (PwC Global Digital Operations Study, 2022).

The application extends beyond fixed assets to fleet management, where AI systems monitor vehicle health in real-time, optimizing maintenance schedules and extending asset lifespans. FedEx’s predictive analytics system for aircraft maintenance has helped increase fleet availability by 15%, directly impacting their ability to meet delivery commitments (FedEx Annual Report, 2023).

Supply chains face numerous risks, including fraud, counterfeiting, theft, and compliance violations. AI enhances risk management through:

Organizations that use AI for fraud detection have seen a 60% reduction in financial losses when compared to those that use traditional approaches, according to the Association for Financial Professionals (AFP Fraud Survey, 2023).

In this regard, the pharmaceutical sector has been very active, with firms such as Merck utilizing AI to prevent fake drugs from getting into genuine supply chains. In order to protect patient safety and brand integrity, their technology examines millions of data points to find questionable trends (Pharmaceutical Manufacturing, 2023).

Supply chain decisions are increasingly being influenced by environmental considerations, and artificial intelligence (AI) offers strong tools for sustainable operations:

While cutting operating expenses, Unilever’s AI-powered sustainability platform has assisted in reducing carbon emissions by 65% per ton of product (Unilever Sustainable Living Plan, 2023).

AI offers the data-driven insights required for businesses pursuing ESG (Environmental, Social, Governance) objectives to achieve significant progress while preserving business performance. Sustainability is now a measurable, achievable goal thanks to technology that makes it possible to precisely assess the environmental impact across intricate global supply networks.

AI dramatically improves operational efficiency across the supply chain by:

According to an Accenture study, the use of AI in supply chains increased worker productivity by 40% on average and decreased transactional activity time by up to 65% (Accenture Technology Vision, 2023).

This productivity enhancement extends throughout the organization:

For employees, AI serves as an intelligence amplifier rather than a replacement, augmenting human capabilities and allowing focus on higher-value activities that require creativity, relationship management, and strategic thinking.

AI has a significant and varied financial influence on supply chain management.

According to Capgemini’s research, companies who integrate AI into their supply chains see an average 15% decrease in costs while also enhancing service quality (Capgemini Research Institute, 2023).

By determining where investments will generate the highest returns, AI facilitates more efficient capital allocation in addition to direct cost savings. In capital-intensive sectors like manufacturing and logistics, where choices about physical assets have long-term financial ramifications, this skill is especially beneficial.

In supply chain processes, human error can lead to serious issues including faulty orders, erroneous projections, shipments, or noncompliance with regulations. AI dramatically reduces these errors through:

Medication mistakes have been cut by up to 96% in healthcare supply chains that use AI-powered verification tools, directly improving patient safety (Healthcare Purchasing News, 2023).

With an accuracy of 99.7% in production compared to 86–92% for human inspectors, AI quality control solutions can drastically cut down on warranty claims and returns (production Technology Insights, 2023).

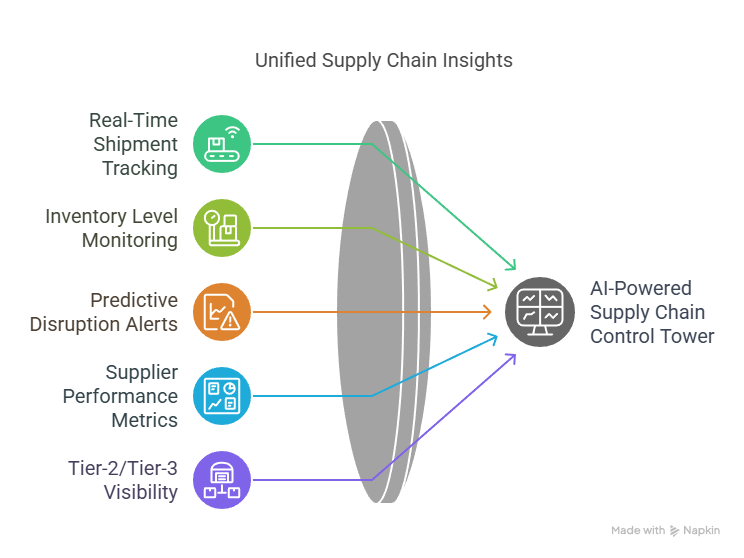

Perhaps the most transformative benefit of AI in supply chain management is the unprecedented visibility it provides across complex networks:

In 2019, only 6 percent of businesses said they had full supply chain insight, according to a Geodis poll. That percentage rises to 65% with businesses using AI-driven control towers (Geodis Supply Chain Worldwide Survey, 2023).

This visibility makes it possible for what McKinsey refers to as the “self-healing supply chain”—one that is able to identify possible issues and automatically put fixes in place before interruptions affect consumers. Businesses with AI-driven visibility capabilities were three times more likely than those without to report little impact during the COVID-19 pandemic (McKinsey Global Institute, 2023).

The ultimate measure of supply chain performance is customer satisfaction, and AI delivers improvements through:

According to a Salesforce study, companies that integrated AI into their customer-facing supply chain operations witnessed an average 15-point rise in Net Promoter Scores (Salesforce State of the Connected Customer, 2023).

When compared to conventional methods, AI-driven inventory optimization has been demonstrated to improve flawless order rates (complete, on-time, and damage-free) in the retail industry by as much as 20% (Retail TouchPoints, 2023).

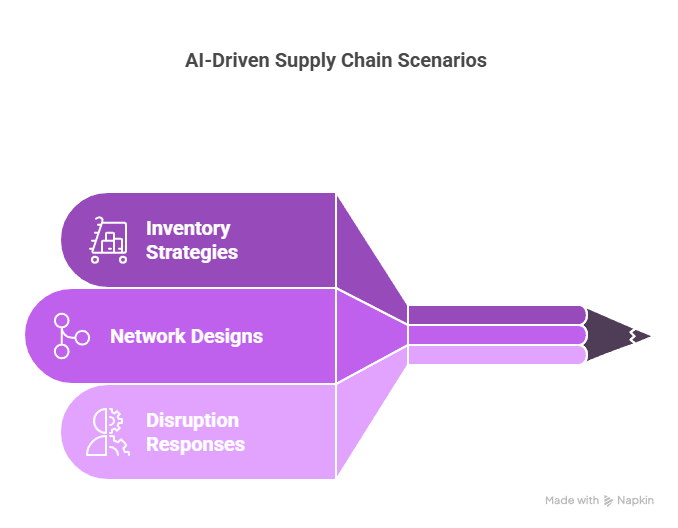

The emergence of sophisticated generative AI models like GPT-4 and others is opening new frontiers in supply chain management:

According to Gartner, by 2025, more than 30% of large businesses will be using generative AI to supply synthetic data for training in order to enhance the capabilities of other AI models without posing privacy issues (Gartner Emerging Technology Roadmap, 2023).

Top logistics businesses are already working with generative AI to create synthetic disruption scenarios to evaluate supply chain resilience before real-world disasters like combined port strikes, severe weather, and geopolitical tensions actually occur.

The next evolution in supply chain AI involves autonomous agents that can:

Boston Consulting Group predicts that by 2026, 30% of routine supply chain decisions will be fully automated through AI agents, allowing human professionals to focus exclusively on exceptions and strategic initiatives (BCG Henderson Institute, 2023).

These autonomous systems represent a fundamental shift in supply chain management—from humans using AI tools to AI systems operating independently with human oversight. To make sure these systems are in line with corporate goals and moral principles, the shift will call for new governance models, control structures, and performance indicators.

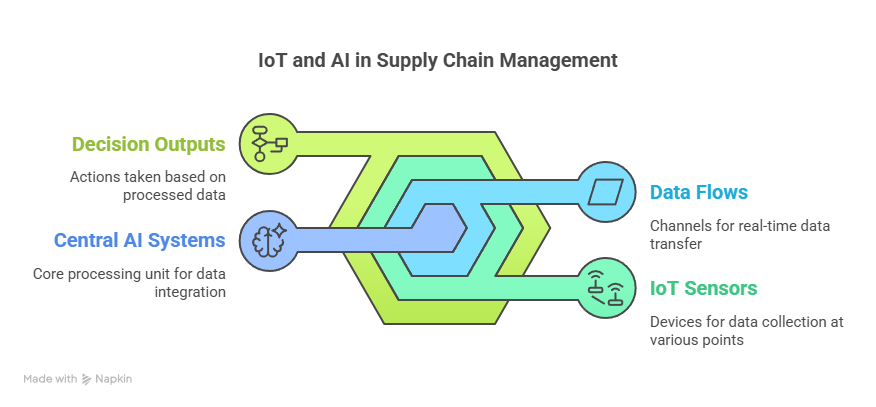

The proliferation of IoT devices is creating an unprecedented stream of real-time data from across the supply chain:

By 2026, there will be over 75 billion connected IoT devices worldwide, many deployed throughout supply chains (IoT Analytics, 2023).

AI serves as the intelligence layer that transforms this torrent of data into actionable insights. The combination enables truly responsive supply chains that can:

Companies implementing integrated IoT-AI solutions report 32% faster response times to supply chain disruptions compared to those using either technology alone (IDC FutureScape, 2023).

The combination of blockchain and AI technologies offers compelling benefits for supply chain transparency and security:

By using blockchain and artificial intelligence (AI) to track food items across intricate supply chains, IBM’s Food Trust platform cuts the time it takes to pinpoint the cause of foodborne illness outbreaks from weeks to seconds (IBM Industry Solutions, 2023).

The use of this technological convergence extends beyond food safety to include regulatory compliance documentation, ethical source verification, and counterfeit protection. According to the World Economic Forum, integrating blockchain technology with artificial intelligence could save $38 billion a year in trade paperwork expenses worldwide (WEF Future of Digital Economy, 2023).

AI is changing the boundaries of efficiency, responsiveness, and resilience in a variety of applications, including demand forecasting and autonomous logistics. AI has an impact on all aspects of the supply chain, as this article has examined:

The competitive advantage gained by early adopters is substantial. According to PwC, companies with mature AI-driven supply chains achieve 7-10% higher profit margins than industry averages (PwC Digital IQ Survey, 2023).

However, technology alone is not enough for successful deployment. To properly utilize AI’s potential, organizations must create the proper personnel, procedures, and governance structures while controlling related risks and moral dilemmas.

Looking ahead, much more change is anticipated as generative AI, autonomous systems, IoT, and blockchain come together. The supply chains of the future will be genuinely intelligent, able to learn, adapt, and change in response to a constantly shifting global business environment, in addition to being effective and robust.

Image prompt: Create a professional marketing visual for Code Brew’s AI supply chain solutions. Show a modern, sleek interface with multiple connected modules for different supply chain functions. Include the company logo prominently, along with key selling points and benefit statements. Use a professional blue/teal color palette suitable for a tech company.

At Code Brew, we specialize in developing cutting-edge AI solutions that transform supply chain operations for businesses of all sizes. With over a decade of experience implementing intelligent systems across manufacturing, retail, logistics, and distribution sectors, we understand the unique challenges of modern supply chains.

Ready to Transform Your Supply Chain?

AI-driven supply chains have obvious competitive advantages, but implementation skills determine whether a project succeeds or fails. In addition to technology, Code Brew provides collaboration during your transformation process. Our supply chain AI specialists will examine your present processes and pinpoint certain areas where AI may be used to enhance them. You will acquire important insights and a possible transformation plan in just 30 minutes.

Don’t let your competition gain the advantages of AI while you fall behind. Contact us today to begin your journey toward an intelligent, resilient, and efficient supply chain.